Subsea Production: The Deep-Water Frontier of Offshore Oil & Gas

Subsea Production: The Deep-Water Frontier of Offshore Oil & Gas

Blog Article

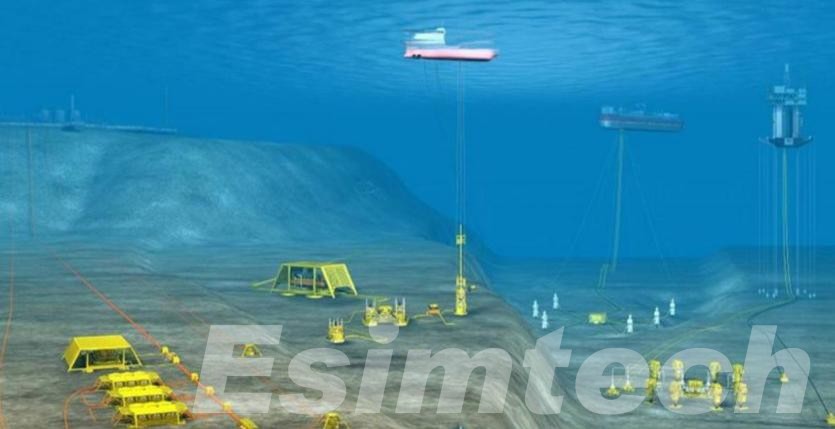

As global demand for hydrocarbons continues to climb, offshore exploration is pushing ever farther from shore and into deeper water. In this environment, subsea systems have emerged as the preferred development architecture, replacing or supplementing fixed jackets and floating platforms with a seabed network of manifolds, tree units, and processing modules. By shifting critical hardware below the wave zone, operators gain flexibility, boost recovery, and reduce exposure to harsh surface conditions.

Why Subsea?

Compared with conventional topside facilities, subsea production systems offer five clear advantages:

- Exceptional adaptability. Whether in 100 m or 3,000 m of water, a modular subsea layout can be tailored to reservoir depth and metocean conditions.

- Minimal surface footprint. Weight and deck space once consumed by pumps, separators, and manifolds move to the seabed, trimming topside payloads and construction costs.

- Long-distance tie-backs. By conditioning the wellstream subsea—or even boosting multiphase flow—fields can be connected to remote host facilities that would otherwise lie beyond economic reach.

- Higher recovery and faster ramp-up. Closer-to-reservoir separation and artificial-lift options reduce back-pressure, accelerating drawdown and extending plateau life.

- Improved safety and economics. Removing high-pressure flowlines from crewed installations lowers risk, while unmanned seabed hardware supports leaner operating models.

Global Leadership—And China’s Catch-Up Curve

Norway, the United States, and Brazil hold the technical high ground after three decades of deep-water projects. China, by contrast, has historically focused on shallow-water blocks (<300 m), but the country’s Blue-Economic Corridor strategy is now directing capital toward local deep-sea R&D.

Mastery of subsea production systems stands at the center of that agenda, with pilot trees and manifolds already deployed in the South China Sea.

Core Hardware: Wellhead & Christmas Tree

The Christmas tree is the beating heart of any subsea project—a pressure-control and flow-routing hub installed directly on the wellhead. Its job is to regulate production, provide monitoring points, and act as a gateway for down-hole interventions. Two main configurations dominate today’s market:

Vertical Christmas Trees (VXT)

In a VXT, valves are stacked above the tubing hanger, mirroring familiar onshore practice. The layout is compact, but intervention windows can be tighter, and workovers often demand full tree removal.

Horizontal Christmas Trees (HXT)

Here, critical valves sit perpendicular to the tubing hanger, surrounding it radially. HXTs accept larger tubing sizes and simplify workovers—technicians can access down-hole equipment without pulling the entire tree. For this reason, they have become the default choice in modern deepwater projects.

Design Challenges. Whether vertical or horizontal, every tree must withstand extreme external pressures, resist corrosion, maintain leak-tight seals for decades, and manage heat loss that could trigger hydrate or wax formation. Materials selection, insulation schemes and redundant controls are therefore key to reliable long-term service.

Control & Monitoring

Subsea valves and sensors communicate with topside or onshore control rooms through electro-hydraulic umbilicals. Redundant fibre optics deliver real-time data—pressure, temperature, vibration—while electrically actuated pods execute commands within seconds. Emerging solutions, such as wireless acoustic telemetry and resident autonomous intervention drones, promise further cost and risk reductions.

The Road Ahead

Industry analysts expect global subsea tie-back volumes to double within a decade, driven by new giant discoveries off Guyana, East Africa, and the Eastern Mediterranean. For newcomers like China, partnerships,

local content initiatives and aggressive field trials will be critical to closing the technology gap. In the longer run, digital twins and predictive analytics could make fully autonomous seabed factories—capable of multi-phase separation, boosting, and even chemical EOR—an achievable reality.

From the Arctic to the pre-salt, subsea systems are reshaping offshore project economics.

Their ability to condense surface functions into modular underwater packages delivers the trifecta of higher recovery, lower risk, and attractive lifecycle costs. As China and other emerging deep-water nations ramp up investment, mastery of design, fabrication, and operation will determine who wins the next chapter of the offshore story.